Dryer

Reliable performance and worldwide track record supported by our heat and circulated air technology.

Drying is an important process which affects product quality and production speed. Among our various dryer systems which have been developed base on our "heat and circulated air" technology, you can select the right dryer system best suitable for your needs.

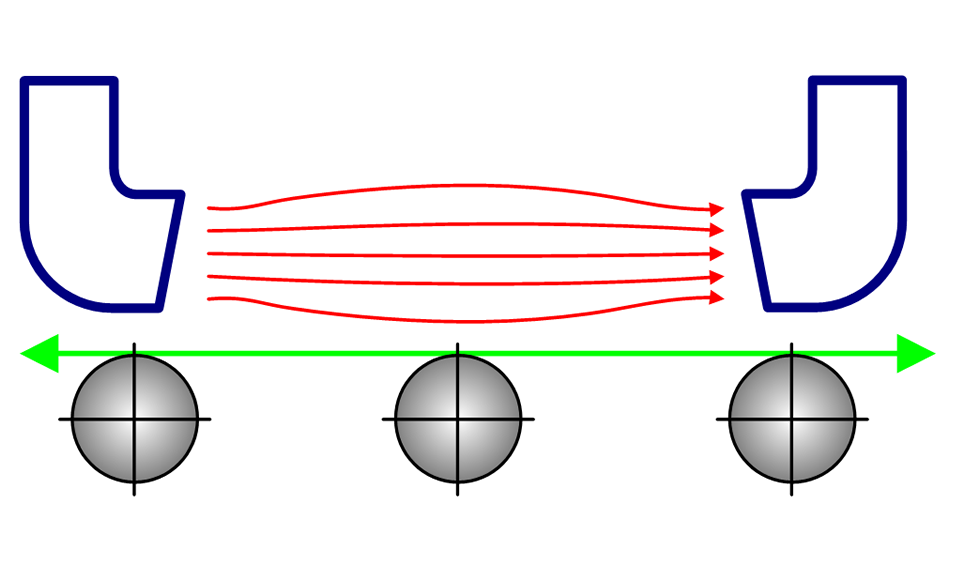

Nozzle variations

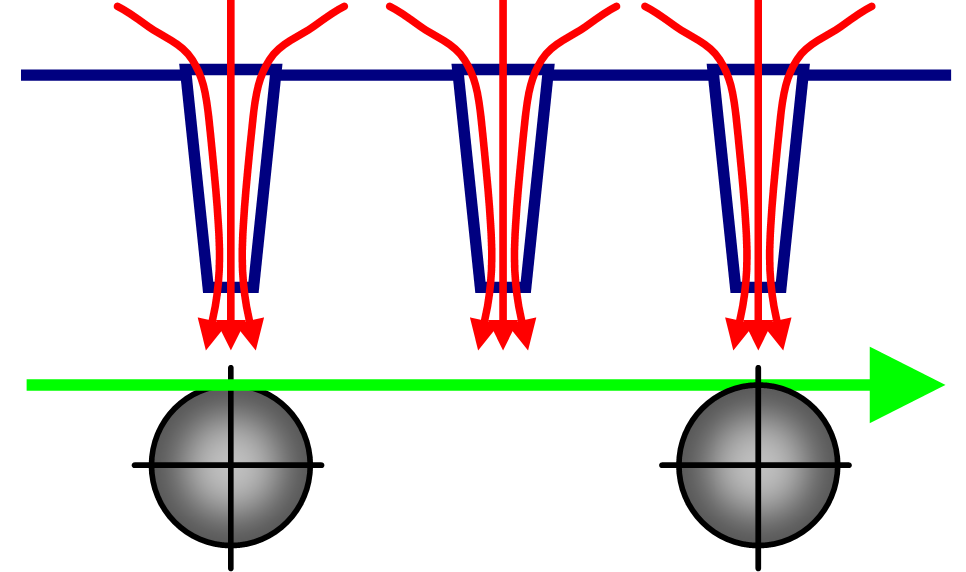

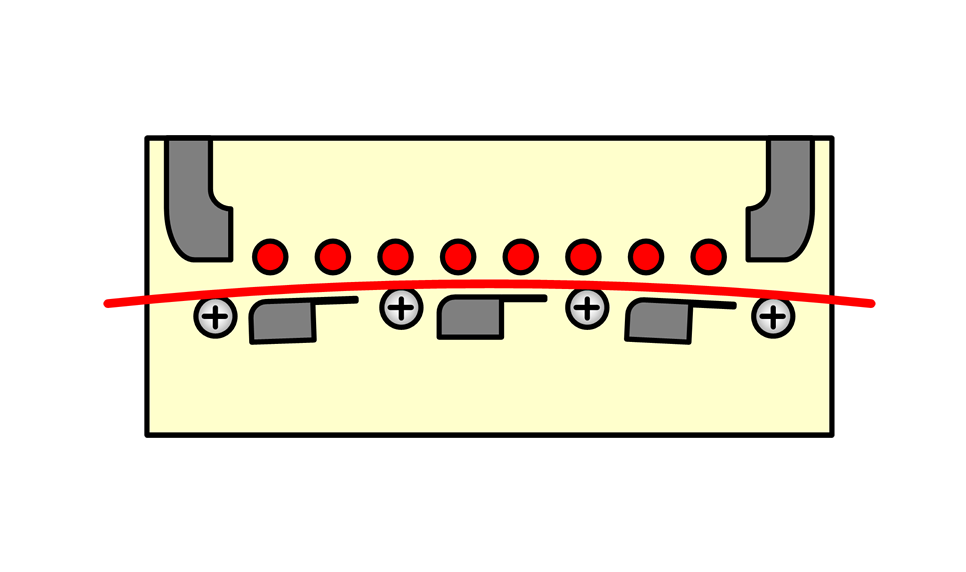

Jet nozzle

- Highly versatile. Suitable for a wide range of applications from low to high heat transfer drying

- Stable substrate traveling assured by the roll support

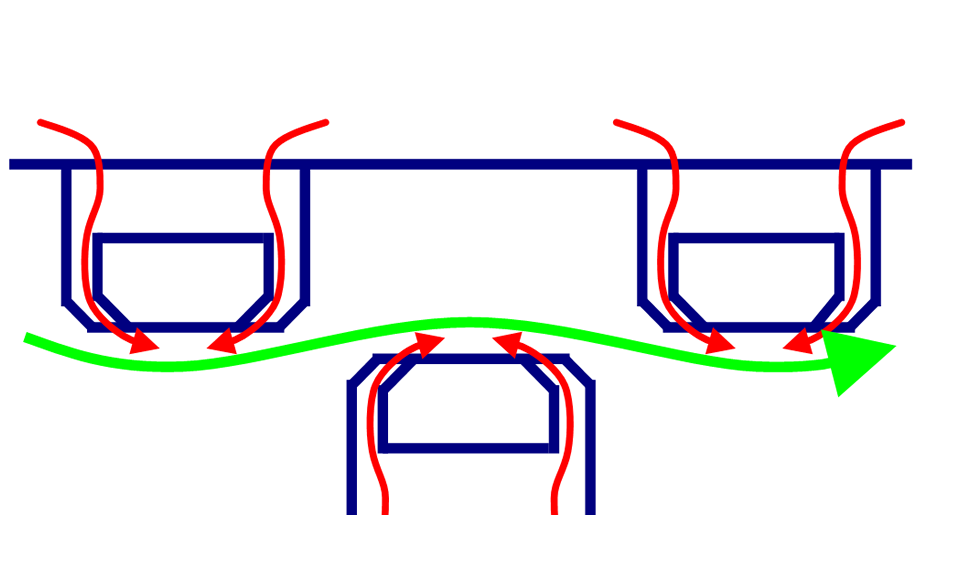

Floating nozzle

- High heat transfer drying

- Non-contact transfer by air floating

Airfoil nozzle

- Suitable for medium to high heat transfer drying

- Non-contact feeding of the substrate by air floating

- Stable substrate traveling is assured by using the roll support

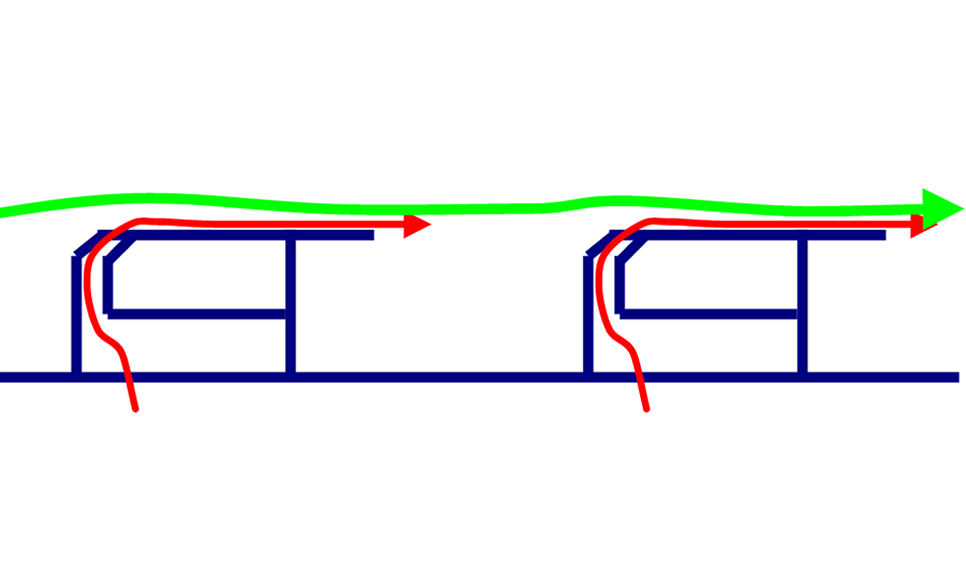

Punching nozzle

- High air-volume and low air-speed nozzle

- Suitable for a wide range of applications from low to medium heat transfer drying

- Stable substrate traveling by the roll support

Counter-flow nozzle

Parallel flow nozzle

- Mild drying has only a slight effect on the coated surface

- Low heat transfer drying

- Stable substrate traveling by the roll support

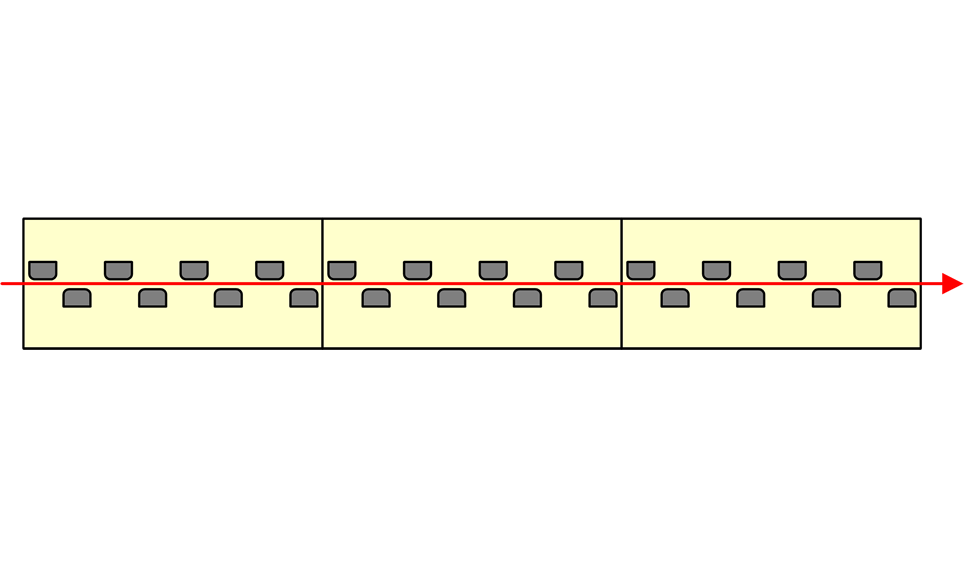

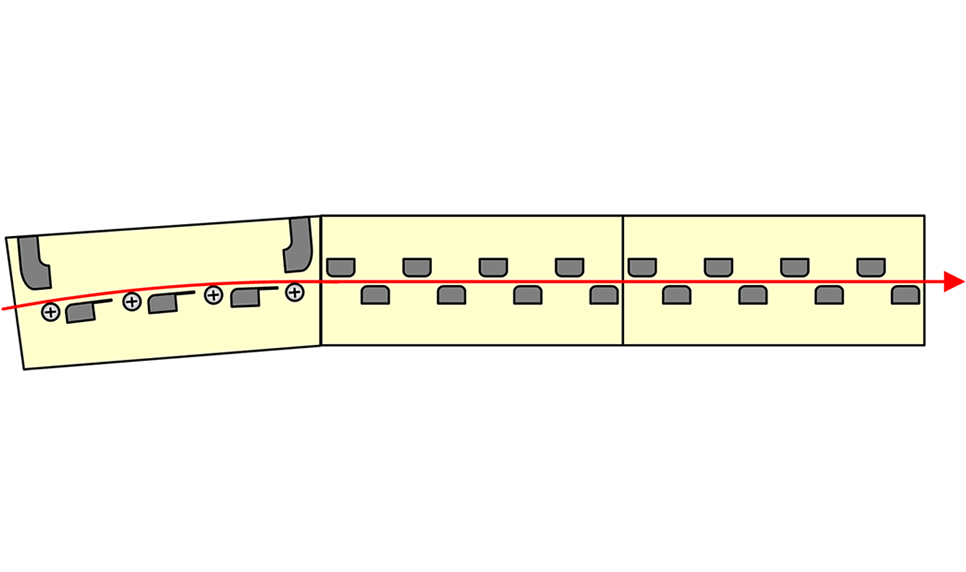

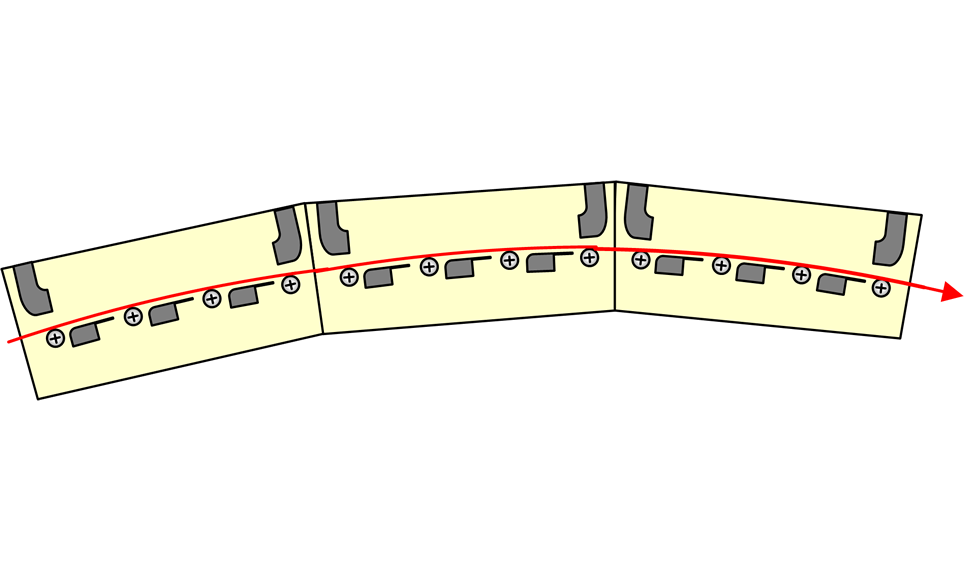

Dryer layout examples

All chambers: Floating type

- Non-contact drying

- High heat transfer drying for the whole zone

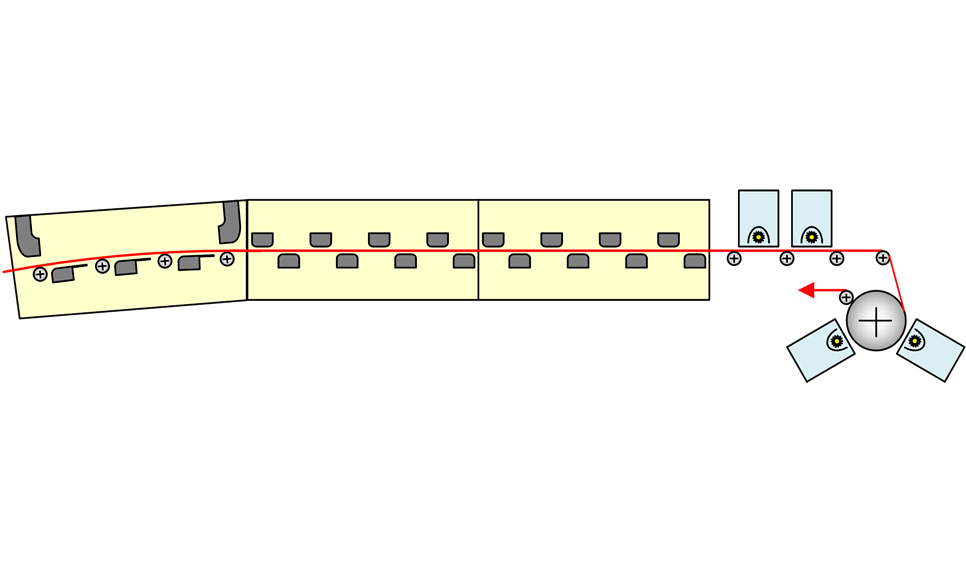

First half: Roll support type

Second half: Floating

- Mild drying at the early stage

- High heat transfer drying and non-contact drying at second half area

All chambers: Roll support type

- Can be used for standard dryer systems

- Possible to change heat transfer conditions flexibly

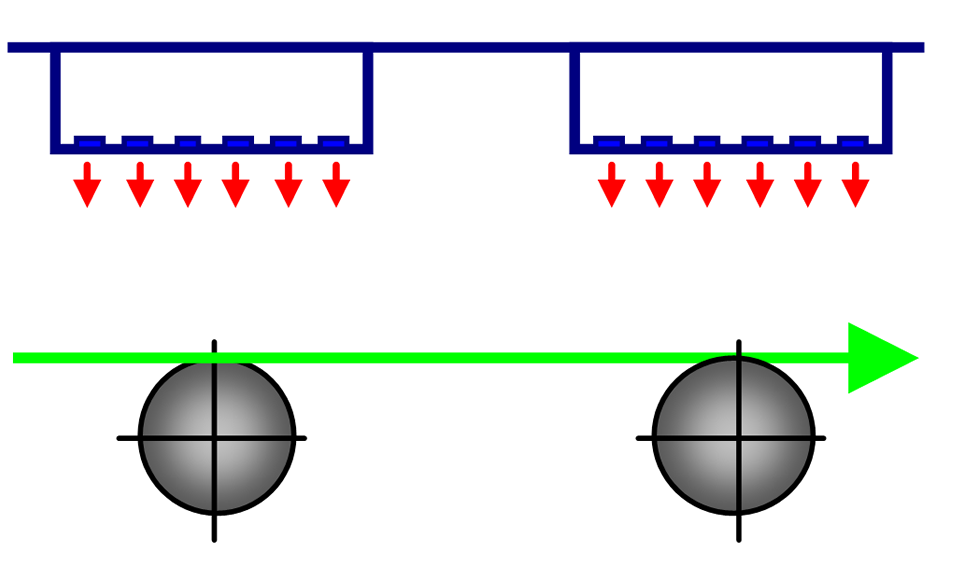

Combination with IR drying

- Drying is promoted from inside the coat to suppress the formation of film on the surface and roughening of the coated surface.

- High drying efficiency due to a combination of hot-air drying and IR drying

Combination with UV device

Inquiry

To find more about HIRANO TECSEED coaters, dryers, and other peripheral equipment, contact us using the form below.