Gravure Coater

A gravure coater is a kind of roll coater, in which the resin is applied to an engraved roll. Typically a blade scrapes the resin off, leaving an appropriate amount in the engraved cells, and the remaining resin in the cells is then transferred to the substrate to form a film.

There are many different types of this method, depending on the roll configuration, transfer method, and blade structure.

All of these types are widely used as they are mostly suitable for thin coating, while easily accommodating high speed and high versatility.

Various patterns of combinations are available other than those described below.

Introducing Gravure Coater

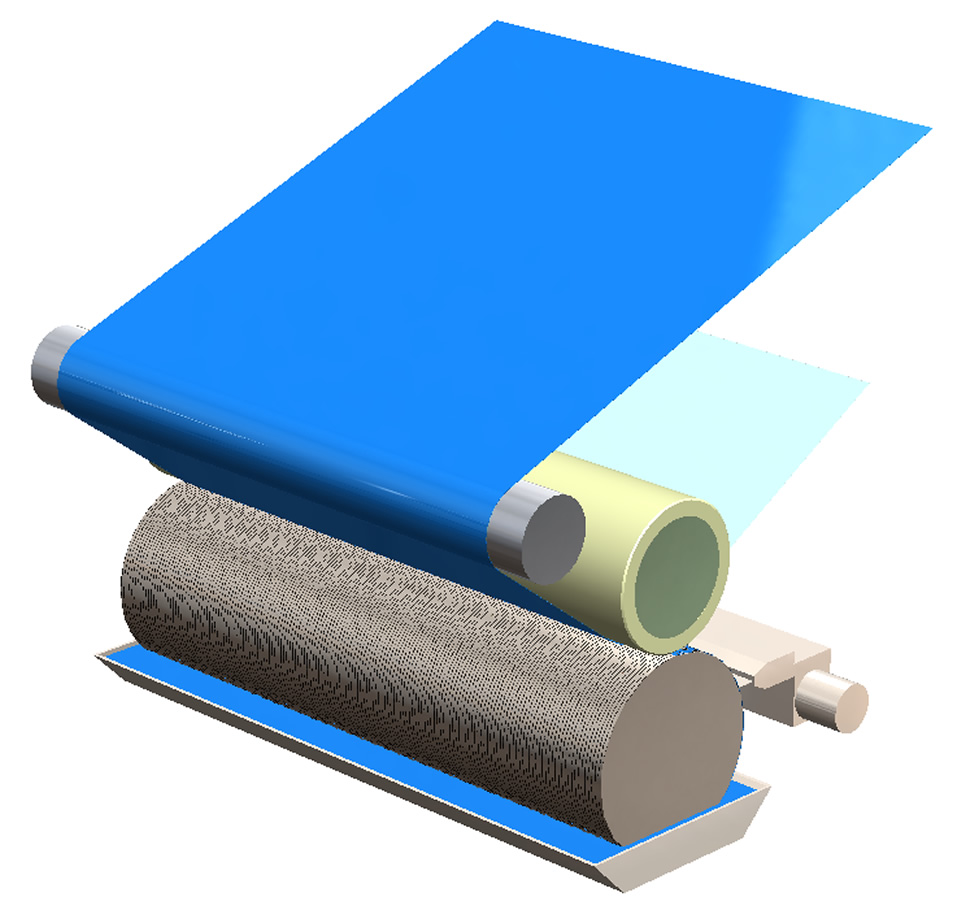

Gravure Direct, Gravure Reverse

This is the basic form of the gravure method and is suitable for thin and high speed coating applications. Smoothing device are often added to make coatings surface flat.

Features

Low coating amount, low viscosity resin applications

- Reference range of application

- Coating speed:1~300m/min

- Viscosity:1~500mPa・s

- Coating amount:1~100μm・Wet

- Use examples:Release agents, primer applications, adhesive coating, functional material coating, etc.

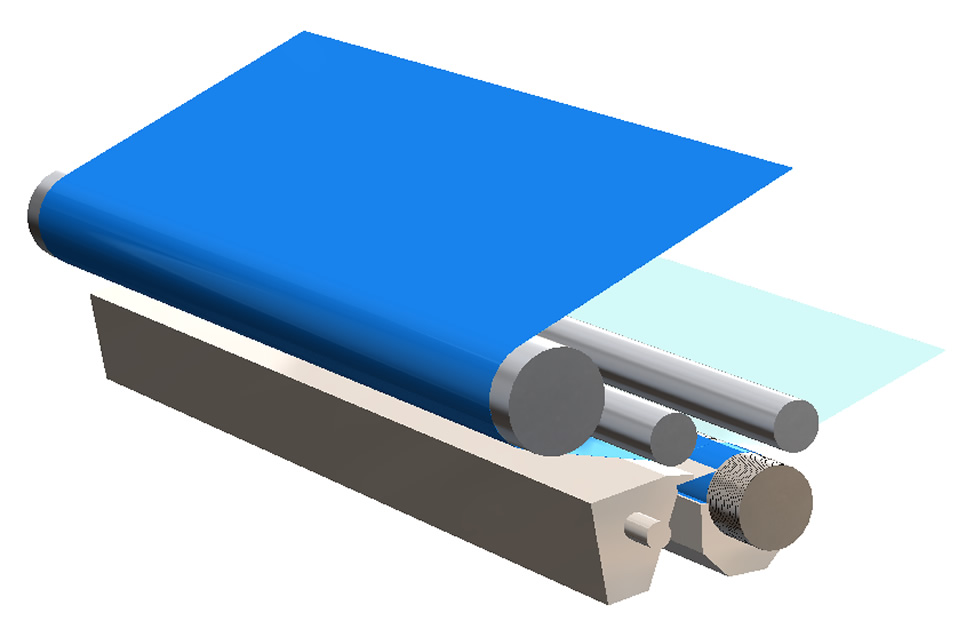

Kiss Reverse Gravure

A method in which transfer in the gravure reverse method is done using the kiss touch style. In comparison to the direct method, this method stresses the substrate less and results in a good coating surface. As it uses kiss transfer, it is likely to be affected by the substrate side conditions, and it is not well suited for high speed coating.

Features

Low coating amount, low viscosity resin applications, good coating surface, good coating quality

- Reference range of application

- Coating speed:1~100m/min

- Viscosity:1~500mPa・s

- Coating amount:1~100μm・Wet

- Use examples:Optical functional materials, release agent coating, etc.

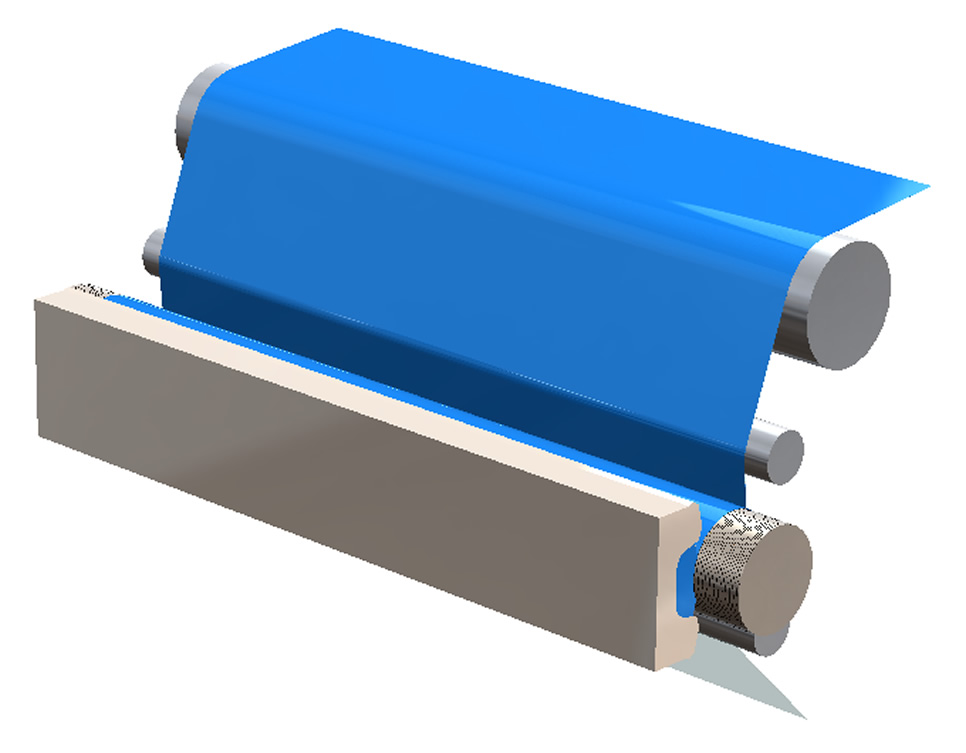

Doctor Chamber Gravure

This method has a structure in which the fluid supply system is integrated with the doctor blade, contributing, in particular, to high speed coating processing. It is effective in removing air entrainment and reducing splash of fluid, and the like. Compared to the gravure method, which is an open system, this is a semi-closed system that has a lower impact on the ambient environment.

Features

High speed coating, low coating amount, high quality coating

- Reference range of application

- Coating speed:1~500m/min

- Viscosity:1~5000mPa・s

- Coating amount:1~100μm・Wet

- Use examples:Release agent coating, functional material coating including for optical use, etc.

Inquiry

To find more about HIRANO TECSEED coaters, dryers, and other peripheral equipment, contact us using the form below.