Comma Coater

These are the methods in which resin film is formed using the gap adjacent to the substrate.

This group of coating methods allows for high precision coating with simple configuration, with good cleaning properties.

A typical coating method in this group is a comma direct method, which is widely recognized as one of the most fundamental coating methods.

Comma Coater® and Comma Roll® are TM of HIRANO TECSEED.

Introducing Comma Coater®

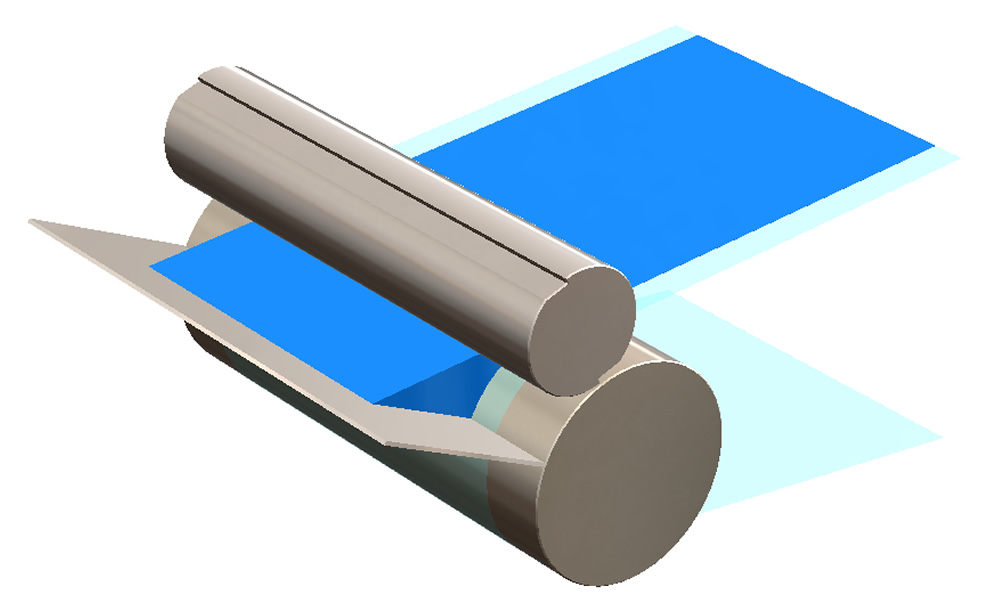

Comma Direct

In this method, a film is formed by letting the substrate move through a gap created between the comma roll® and the back roll.

Suitable mainly for medium to high viscosity, for producing medium thickness film coating.

This method allows for high cleaning properties, suitable for production of many different types in smaller quantities.

With this method, coating can be done with a smaller amount of coating fluid. This method is often used in R&D applications.

Features

Precision coating, good cleaning properties, simple handling.

- Reference range of application

- Coating speed:0.1-200m/min

- Viscosity:300-100000mPa・s

- Coating amount:30-2000μm・Wet

- Use examples:Adhesives, electronic materials (FCCL,Circuit boards, and Electrostatic chucks), medical drugs, etc.

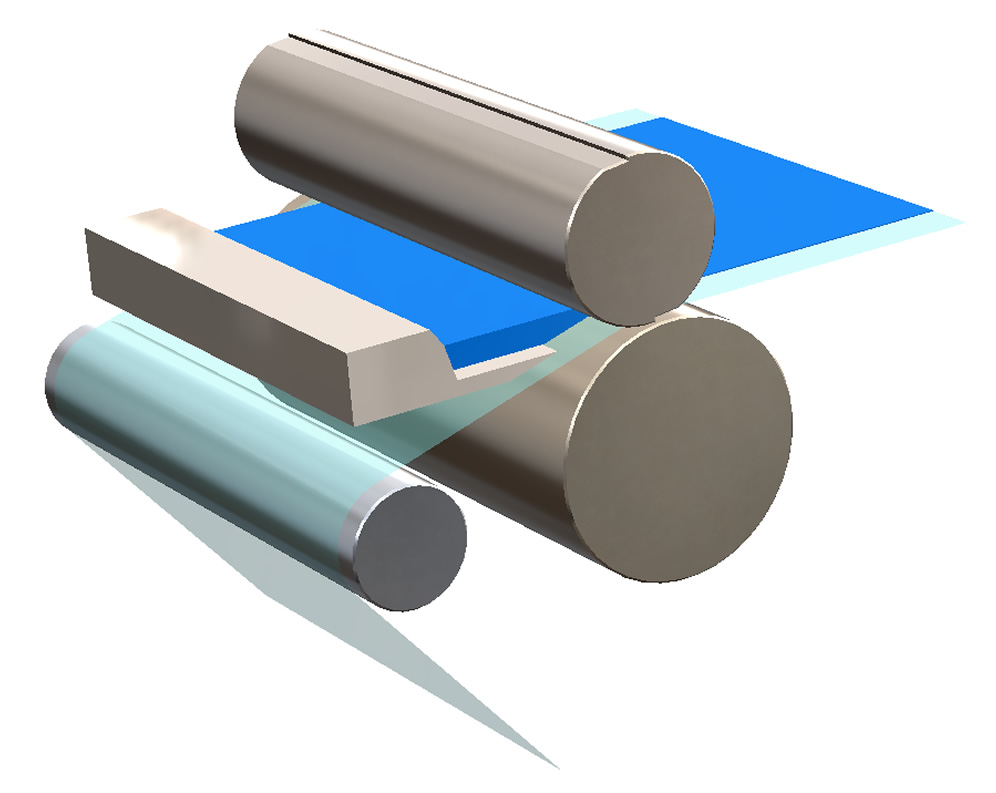

Comma Direct (Box Type)

This is one of comma direct coating methods that is particularly suitable for thick coating.

This method allows coating with a wider gap, with a structure in which coating fluid is supplied evenly and fluid flowing is prevented.

Features

Precision coating, good cleaning properties

- Reference range of application

- Coating speed:0.05-10m/min

- Viscosity:300-50000mPa・s

- Coating amount:50-2000μm・Wet

- Use examples:Electronic materials (Circuit boards, Electrostatic chucks, and Piezoelectric elements), etc.

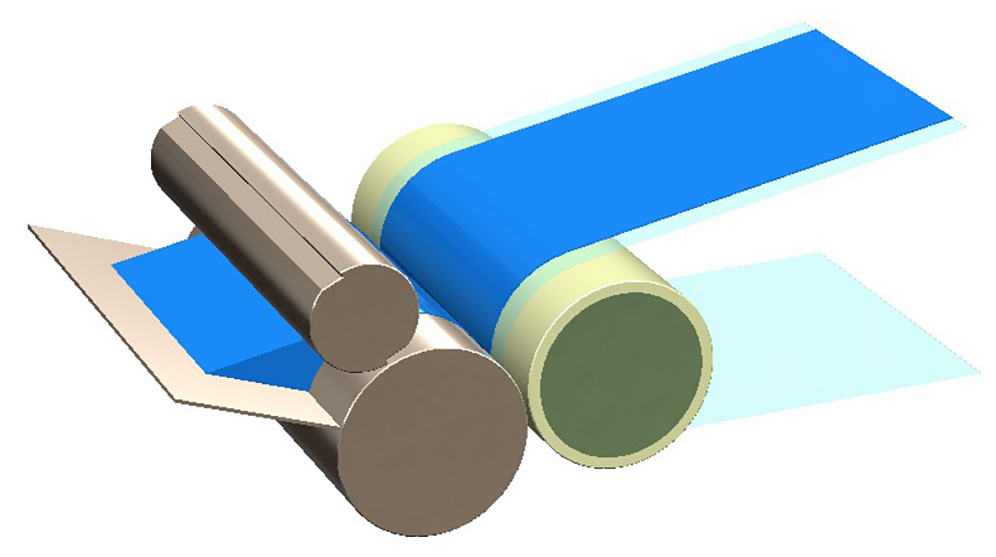

Comma Reverse

In this method, a rubber transfer roll is added to the comma method, resulting in a contouring coating method with features similar to comma direct. This method is used when it is desirable to have a shorter resin wetting length, or when it is not desirable to make the substrate run through a narrow gap. This method also allows for intermittent coating.

Features

Precision coating, intermittent-patterned coating, good cleaning properties, simple handling

- Reference range of application

- Coating speed:0.1-200m/min

- Viscosity:100-50000mPa・s

- Coating amount:20-500μm・Wet

- Use examples:Adhesives, battery electrodes, etc.

Inquiry

To find more about HIRANO TECSEED coaters, dryers, and other peripheral equipment, contact us using the form below.