Our Business

Based on its "heat and circulated air" and "coating and line control" technologies cultivated over many years, HIRANO TECSEED strives for the establishment of basic technology, applying its rich experience in systematization technology, and further promoting innovative technology development.

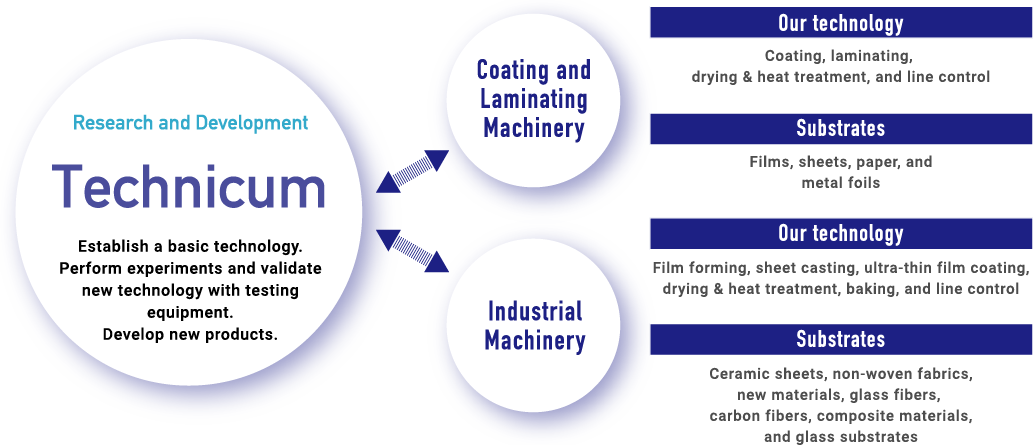

In order to specialize and improve the efficiency of our technology, developed equipment is classified into two types based upon the object base materials of each: coating/laminating machinery (film, sheet, paper, metal foil) and industrial machinery (non-woven fabric, glass fiber, carbon fiber, new material, composite material, glass substrate).

Technicum, which encapsulates all the HIRANO TECSEED technologies to establish a basic technology, operates R&D to support our customers' product development, utilizing a testing facility of a similar scale to the production facility.

Not only is the R&D division developing thin film coating technology, it has started to challenge itself in the fields of nanotechnology and materials, combining wet and dry coating technology toward the next generation.

Quality control supported by modern facilities and superior work effort

Material warehousing and a constant flow of machinery manufacturing, assembly, painting, packing, and shipping: Each work area is systematically organized and operates as a highly efficient production line.

Our huge assembly plant realizes machine assembly to a height of 10 m and an overall length of 100 m. The plant has completely integrated electrical loading facilities that can set up a number of voltage levels, 50/60 Hz, to satisfy the needs of the final installation.

We can guarantee a high level of quality in our machinery manufacturing, which has the advantage of totally integrated modern facilities for machining, metal board forming, piping, parts assembly, and stainless steel and aluminum processing.

Quality control and workplace improvement program as part of our everyday life

Our quality control program has a long history that started in 1966 with the ZD program, and continues with IE, VA, Diamond Operation, Attack 80, and a host of other improvement programs right up to today's TQC activity.

These activities improve everyday working conditions for every one of our employees and encourage suggestions from them.